When it comes to agriculture water treatment processes, you've probably heard the saying, 'An ounce of prevention is worth a pound of cure.' Imagine the impact of clean water on your crops' health and yield.

The step-by-step guide we're about to embark on will unveil the secrets to ensuring your agricultural water is free from contaminants, enhancing not only your irrigation systems' efficiency but also the overall success of your farming endeavors.

So, are you ready to discover the key steps to safeguarding your agricultural water quality and, ultimately, your harvest's prosperity?

Key Takeaways

- Proper water treatment in agriculture is crucial for maximizing crop health and productivity, preventing clogging in irrigation systems, ensuring efficient water distribution, and safeguarding crop yields.

- Different filtration methods such as sand and gravel, activated carbon, and screen filters play a vital role in removing impurities, contaminants, and pollutants from water.

- Chemical treatment options like coagulants, flocculants, chlorination, and pH adjustment are effective in removing suspended particles and disinfecting water in agricultural settings.

- Regular monitoring of water quality, maintenance of water treatment systems, and utilizing UV disinfection technology are essential practices to enhance water quality in agriculture.

Importance of Water Treatment in Agriculture

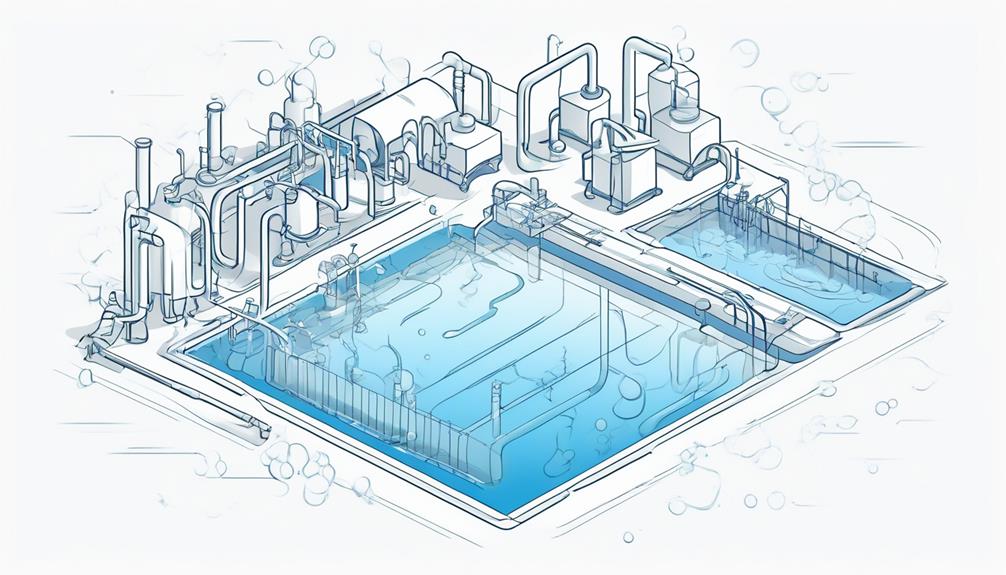

Ensuring the quality and safety of irrigation water through proper treatment is essential for maximizing crop health and productivity in agriculture. Water treatment plays a vital role in agriculture by preventing clogging in irrigation systems, ensuring efficient water distribution, and safeguarding crop yields. Filtration is a key process in water treatment that helps in removing impurities, contaminants, and pollutants from water sources. By employing filtration techniques, you can significantly improve water quality, leading to healthier crops and increased agricultural output.

Regular water quality monitoring is crucial in agriculture to detect any potential issues in water sources promptly. Through monitoring, you can identify any deviations from the desired water quality standards and take necessary corrective actions. This proactive approach ensures that your irrigation water remains clean and safe for your crops, promoting their growth and overall well-being. By incorporating effective filtration methods and implementing rigorous water quality monitoring practices, you can enhance the quality of your irrigation water and ultimately optimize your agricultural production.

Types of Mechanical Filtration Methods

When it comes to mechanical filtration methods, understanding filter media types and filtration efficiency levels is essential. Different pore sizes in screen filters and the use of media and disc filters are key components of these methods.

Picking the right filtration degree and pore sizes can protect your irrigation systems effectively.

Filter Media Types

Sand and gravel filters, activated carbon filters, anthracite filters, multimedia filters, and diatomaceous earth filters are common types of media used in various mechanical filtration methods for water treatment. Each type of filter media serves a specific purpose in the filtration process. Here is a breakdown of the key characteristics of these filter media types:

| Filter Media | Description | Common Uses |

|---|---|---|

| Sand and Gravel | Effective for removing larger particles and sediment from water. | Initial filtration in water treatment |

| Activated Carbon | Ideal for removing organic compounds, chemicals, and odors from water. | Purifying drinking water |

| Anthracite | Widely used for eliminating turbidity and suspended solids in water. | Municipal water treatment plants |

| Multimedia | Utilizes layers of different media like sand, garnet, and anthracite for enhanced filtration. | Industrial water filtration |

| Diatomaceous Earth | Known for removing very fine particles and impurities from water. | Swimming pool filtration systems |

Filtration Efficiency Levels

Shifting focus to the efficiency levels of filtration processes, various mechanical methods, such as surface filtration and depth filtration, play a vital role in maintaining water quality and safeguarding irrigation systems.

Surface filtration, like screen filters, utilizes different pore sizes, while depth filtration, including media filters, and semi-depth filtration, such as disc filters, are commonly employed methods in filter systems.

The filtration degree is crucial in protecting irrigation systems from damage, with nominal and absolute filtration degrees determining pore sizes. Effective filtration area, which is the usable space for the filtration process, significantly impacts the overall efficiency of filtration systems.

Understanding these mechanical filtration methods helps in selecting the right filter system for optimal agricultural water treatment.

Selecting the Right Screen Filter

When starting the selection process for a screen filter for your agricultural irrigation system, ensure to consider the flow rate and water characteristics to optimize filtration efficiency.

Here are four crucial steps to guide you through selecting the right screen filter:

- Evaluate Flow Rate and Water Source: Determine the volume of water passing through the system and analyze the impurities present in the water source.

- Check Cleaning Technology: Look for screen filters with efficient self-cleaning mechanisms to reduce maintenance needs and ensure continuous operation.

- Assess Filtration Degree: Consider the level of filtration required based on the type and size of particles present in the water to choose the appropriate screen filter.

- Consider Maintenance Needs: Select a screen filter with a simple design and effective cleaning process to ensure longevity and sustained filtration efficiency.

Before and After Filtration Process Example

Before filtration, your water is laden with a variety of impurities like salts, bacteria, and algae. However, after undergoing the filtration process, these contaminants are efficiently eliminated.

The filtration procedure involves both coarse and fine screens to remove particles and a self-cleaning mechanism triggered by pressure fluctuations, ensuring your water is clean and safe.

Filtration Process Overview

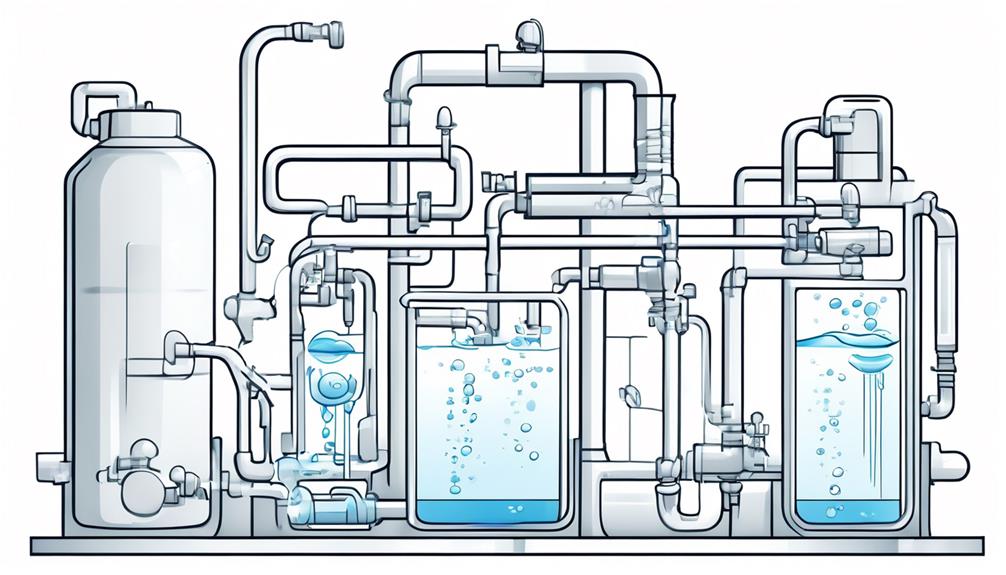

To understand the Filtration Process Overview (Before and After Filtration Process Example), it's essential to grasp the significance of pre-filtration in removing various impurities from raw water. Here's a breakdown:

- Pre-Filtration: Raw water is laden with salts, viruses, bacteria, clay, silt, algae, sand, and gravel, which need removal before further processing.

- Filtration Process: Through coarse and fine screens, water particles are eliminated, enhancing water quality significantly.

- Post-Filtration: After undergoing filtration, water is devoid of impurities and contaminants, making it suitable for various uses like drinking, industrial activities, or irrigation.

- Cleaning Technology: Effective cleaning methods play a crucial role in thoroughly eliminating impurities and preventing filter blockages, ensuring continuous clean water supply.

Understanding these steps in the filtration process overview is vital to appreciate the transformation of water quality from raw to purified, free from organic compounds.

Contaminant Removal Techniques

As you move from understanding the Filtration Process Overview to exploring Contaminant Removal Techniques, the focus shifts towards eliminating specific impurities and ensuring water quality meets stringent standards.

The first step in the process involves pre-filtration methods such as screening, grit removal, and odor control to eliminate large particles and odors before the main filtration process begins.

After pre-filtration, mechanical filtration techniques like screen, media, or disc filters, along with chemical processes like coagulation and sedimentation, are used to remove contaminants from the water.

Activated carbon plays a crucial role in removing organic contaminants. These processes are vital for safeguarding equipment, ensuring impurity removal, and producing clean water for various agricultural uses.

Water Quality Improvement

Improving water quality through effective filtration processes is essential for ensuring the safety and cleanliness of water used in agriculture.

Here's an example of how water quality can be enhanced before and after filtration:

Before Filtration:

- Water contains salts, viruses, bacteria, clay, silt, algae, sand, and gravel.

Filtration Process:

- Amiad's method involves particle removal with coarse and fine screens, self-cleaning, forced backwash, and preventing filter clogging.

Selection Importance:

- Efficient technology for particle filtration and cleaning is crucial in choosing the right screen filter.

After Filtration:

- Water is free from impurities and contaminants, ensuring safe and clean water for drinking and agricultural purposes.

Common Water Contaminants in Agriculture

Amidst the diverse array of contaminants that can infiltrate agricultural water sources, salts, viruses, bacteria, and various other particles pose significant challenges to water quality maintenance. Water used in agriculture can be tainted with salts, viruses, bacteria, clay, silt, algae, sand, gravel, pesticides, herbicides, fertilizers, heavy metals like lead, arsenic, cadmium, E. coli, coliform bacteria, and organic matter from decaying plant material and manure. To better understand the range of common water contaminants in agriculture, take a look at the table below:

| Contaminant Type | Examples |

|---|---|

| Salts | Sodium chloride, calcium sulfate |

| Microbial Contaminants | E. coli, coliform bacteria |

| Heavy Metals | Lead, arsenic, cadmium |

Chemical Treatment Options for Water

Utilize coagulants and flocculants to effectively eliminate suspended particles in water through chemical treatment processes. To enhance the removal of large, organic matter, consider the following steps:

- Coagulation: Begin by adding coagulants like aluminum sulfate or ferric chloride to the water. These chemicals neutralize the charges on particles, allowing them to clump together.

- Flocculation: After coagulation, introduce flocculants such as polymers to further bind the particles together, forming larger flocs that are easier to separate from the water.

- Chlorination: Employ chlorine to disinfect the water, eliminating harmful microorganisms and ensuring its safety for agricultural use.

- pH Adjustment: Use lime or soda ash to adjust the pH of the water. This not only aids in the clarification of water but also helps control corrosion in agricultural systems.

UV Disinfection for Agricultural Water

When disinfecting agricultural water, employing UV light is a highly efficient method for eliminating harmful microorganisms and pathogens. UV disinfection works by deactivating the DNA of microorganisms present in the water, preventing them from reproducing. This process is chemical-free, making it an environmentally friendly and sustainable option for treating water systems in agriculture. Ensuring the safety of water used for crop irrigation and preventing the spread of waterborne diseases are crucial factors in agricultural practices.

UV Disinfection Benefits:

| Benefits | Description |

|---|---|

| Effective | Eliminates harmful microorganisms and pathogens from water used in agriculture. |

| Environmentally Friendly | Does not involve the use of chemicals, promoting sustainability in water treatment systems. |

| Critical for Safety | Ensures the safety of agricultural water for irrigation, safeguarding crops and preventing diseases. |

| Low Maintenance | Proper upkeep and monitoring are essential for consistent and reliable disinfection performance. |

| Sustainable Option | A chemical-free method to remove impurities, supporting eco-friendly practices in agriculture. |

Monitoring Water Quality in Agriculture

To ensure the effectiveness of UV disinfection in eliminating harmful microorganisms from agricultural water, monitoring water quality becomes a vital practice in maintaining safety standards and sustainable agricultural practices. Here's how you can effectively monitor water quality in agriculture:

- Regular Testing: Conduct routine tests for parameters like pH, turbidity, dissolved oxygen, and nutrient levels to ensure water quality meets safety standards.

- Utilize Advanced Technology: Employ advanced water quality monitoring equipment to obtain accurate real-time data for informed decision-making.

- Early Issue Detection: Monitoring helps identify potential problems early on, enabling prompt corrective actions to prevent negative impacts on crops, soil, and the environment.

- Optimization and Conservation: Effective water quality monitoring allows farmers to optimize irrigation practices, reduce water wastage, and uphold sustainable agricultural methods.

Maintenance Tips for Water Treatment Systems

For effective maintenance of water treatment systems, regularly inspecting and cleaning filters is essential to ensure efficient removal of contaminants. Filters play a crucial role in safeguarding the quality of your water source, a precious resource that requires protection.

By monitoring pressure differentials and backwash systems, you can maintain optimal filtration performance, enhancing the efficiency of contaminant removal. Additionally, it's vital to keep chemical treatment equipment well-maintained to uphold consistent water quality standards.

Conduct routine checks and calibration of monitoring instruments to accurately assess water quality and ensure the effectiveness of the treatment process. Training personnel on proper maintenance procedures is key to sustaining the system's functionality.

Timely repairs are essential to prevent system downtime, safeguarding the continuous treatment of water from your valuable source. Remember, proactive maintenance is the cornerstone of preserving the integrity of your water treatment system and safeguarding this precious resource for the future.

Frequently Asked Questions

What Are the 7 Steps of Water Treatment?

You start with water collection. Screen out larger particles, add chemicals to form flocs, mix for coagulation, settle floc in sedimentation, clarify water. Seven steps in water treatment: collect, screen, chemically treat, coagulate, settle, clarify, and enjoy clean water.

What Are the 5 Processes of Water Treatment?

In water treatment, screening removes large materials, chemicals induce floc formation for easy removal, coagulation aids in particle removal, and filtration through media like sand or activated carbon further purifies the water, ensuring safe consumption.

What Is the Correct Order for the Steps in a Water Treatment Plant?

To treat water in the correct order at a plant, start with coagulation, then move to flocculation, sedimentation, filtration, and finish with disinfection. Following this sequence ensures effective removal of impurities for safe water.

What Are the 5 Steps of Wastewater Treatment?

In wastewater treatment, the 5 steps are collection, pre-treatment, odor control, screening, and primary/secondary treatment. You collect wastewater, remove harmful items, control odors, screen out debris, and treat with oxygen to break down organics for a cleaner environment.

Conclusion

Now that you've learned the ins and outs of agriculture water treatment, remember: 'An ounce of prevention is worth a pound of cure.'

By implementing proper filtration methods and maintenance tips, you can ensure clean and safe water for all your agricultural needs.

So, don't wait until it's too late – take action now to protect your crops and maximize your harvests.

Happy farming!