Do you ever wonder about the intricate web of challenges that modern water treatment must navigate, akin to a ship sailing through treacherous waters?

From the constant need for skill-building programs to combatting microbial invaders, ensuring precise data monitoring, tackling equipment design complexities, and juggling routine maintenance demands, the journey is far from smooth sailing.

But wait, there's more to uncover beyond these initial obstacles that stir the waters of the water treatment realm. What lies beneath the surface of these challenges?

Key Takeaways

- Comprehensive training programs are essential for staff to understand equipment, maintenance, and monitoring parameters in modern water treatment.

- Proper maintenance and adherence to specifications are crucial to control microbial contamination in water treatment facilities.

- Monitoring UV intensity and disinfection dose is key to ensuring effective disinfection using UV sterilization technology.

- Real-time data monitoring and documentation help in early issue detection and process optimization for enhanced plant performance in water treatment.

Training and Education Programs

To excel in modern water treatment, investing in comprehensive training and education programs is crucial for all staff members, from entry-level to management positions. These programs provide essential knowledge on equipment, maintenance, and monitoring parameters. Basic training ensures understanding of these fundamentals, while advanced programs empower employees to proactively troubleshoot and resolve issues. In-house high-level training plays a vital role in quickly identifying and resolving problems that may arise in water treatment processes.

Through proper training, employees can effectively recognize common issues such as scaling, membrane fouling, bacterial contamination, and equipment failures. This knowledge equips staff with the skills needed to maintain optimal plant performance and ensure water quality standards are consistently met. By investing in ongoing training and education programs, water treatment facilities can cultivate a highly skilled workforce capable of addressing challenges efficiently and effectively.

Microbial Contamination Control

Hey there!

Let's talk about keeping those pesky microbes in check.

Chlorination zaps those germs away, UV sterilization is like a microbial sunburn, and filtration acts as a sieve for cleaner water.

Chlorination for Disinfection

When aiming to control microbial contamination in water treatment, chlorination stands out as a widely adopted method for its effective disinfection properties. Chlorine is commonly used for bacterial control, although UV disinfection is preferred with membrane filtration to prevent damage. Proper monitoring of parameters like UV intensity and disinfection dose is crucial for maintaining water quality. Failure to eliminate oxidizing agents can result in bacterial growth, leading to membrane fouling. Therefore, ensuring equipment maintenance and adherence to specifications are essential for effective microbial contamination control.

| Chlorination for Disinfection | Microbial Control | Water Quality |

|---|---|---|

| Widely adopted method | Crucial monitoring | Maintaining purity |

| Effective disinfection properties | UV intensity checks | Preventing bacterial growth |

| Chlorine vs. UV disinfection | Correct disinfection dose | Avoiding membrane fouling |

UV Sterilization Technology

Harness the power of UV Sterilization Technology to effectively control microbial contamination in modern water treatment systems. UV sterilization is a core competency in ensuring Clean Water by eliminating bacteria in water and wastewater treatment facilities.

This technology is vital for combating the effects of climate change on water use and treatment. UV sterilization plays a crucial role in maintaining the integrity of treatment systems, particularly in industrial water reuse scenarios.

Monitoring UV intensity is essential to guarantee the correct disinfection doses are administered. Remember, proper maintenance of UV equipment, such as quartz sleeves, is key to optimal performance and preventing major issues.

Embracing UV sterilization technology is a proactive step towards safeguarding water quality and protecting public health.

Filtration for Purification

Moving from UV sterilization technology to Filtration for Purification, the focus shifts to controlling microbial contamination through various filtration methods. Filtration for purification is crucial in water treatment, as it helps eliminate harmful bacteria and other contaminants.

To achieve effective microbial control, biocides like chlorine or UV disinfectants are commonly used. Monitoring parameters such as SDI, NPF, pressure, salt rejection, and UV intensity is essential to ensure proper microbial contamination control.

Proper equipment design, specification, and maintenance are also vital to prevent contamination and maintain system efficiency. Implementing preventive measures and promoting industrial water reuse are key strategies in enhancing microbial contamination control and ensuring the sustainability of water treatment processes.

Data Monitoring and Documentation

You know how keeping an eye on real-time data and ensuring accurate documentation can make all the difference in water treatment?

Imagine tracking parameters like SDI, NPF, pressure, salt rejection, and UV intensity to spot issues before they escalate.

Consistent monitoring not only prevents equipment failures but also helps in maintaining the right disinfection levels, making data tracking and documentation indispensable in water treatment.

Real-Time Data Tracking

When monitoring water treatment processes in real-time, immediate identification of deviations from standard conditions becomes possible. Real-time data tracking in wastewater treatment plants is essential for ensuring the efficiency and effectiveness of the treatment process. By continuously monitoring parameters like UV intensity, flow rates, and chemical dosages, operators can quickly detect any abnormalities and take corrective actions promptly. This proactive approach allows for early intervention in issues such as membrane fouling, bacterial growth, and equipment failures, preventing potential system downtime and ensuring the quality of the treated water. Proper data monitoring and documentation enable operators to identify patterns, optimize processes, and implement preventive measures, ultimately improving the overall performance of wastewater treatment plants.

| Real-Time Data Tracking in Wastewater Treatment Plants | Benefits |

|---|---|

| Continuous monitoring of treatment parameters | Early detection of deviations |

| Immediate identification of issues like membrane fouling and bacterial growth | Proactive problem-solving |

| Optimization of processes and preventive measures | Enhanced treatment plant performance |

Documentation Accuracy

Accuracy in documentation is a critical component of ensuring regulatory compliance and evaluating system performance in water treatment processes. Proper monitoring and recording of parameters like SDI, NPF, pressure, salt rejection, and UV intensity is essential for maintaining system efficiency. By ensuring accuracy in data monitoring, you can identify patterns and plan preventive measures for maintenance and troubleshooting, ultimately saving costs and preventing damage to the water treatment systems.

Inaccurate documentation can have serious implications on system performance, leading to increased costs and potential harm to the environment. Documentation accuracy is crucial for demonstrating compliance with environmental regulations and ensuring the safety and integrity of water treatment facilities, especially with the increasing demand for water.

Advanced Equipment Design Challenges

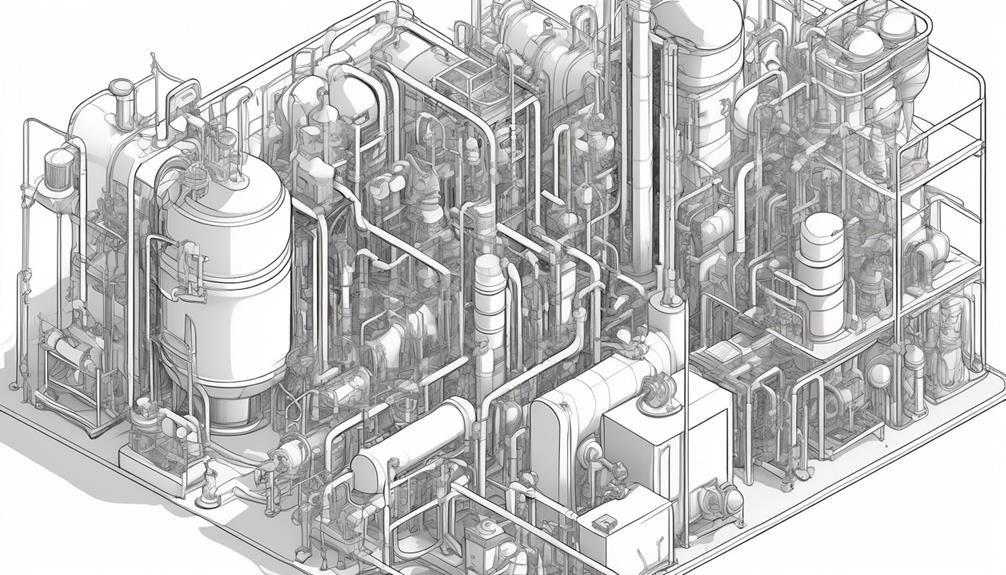

Designing advanced water treatment equipment poses numerous challenges that require a deep understanding of personnel training, bacterial control factors, monitoring processes, and maintenance considerations. When delving into the subject matter of advanced equipment design challenges, here are crucial points to consider:

- Personnel Training: Ensuring that personnel are well-trained and knowledgeable about the intricacies of the equipment is paramount for successful operation.

- Bacterial Control Factors: Managing bacteria effectively involves meticulous attention to variables like temperature, flow rates, and the selection of appropriate biocides.

- Monitoring Processes: Adequate instrumentation and record-keeping play a crucial role in maintaining optimal performance and identifying issues promptly.

- Maintenance Considerations: Proper design, specification, and ongoing maintenance planning are vital to prevent inefficiencies and breakdowns that can disrupt water treatment processes.

Routine Maintenance Requirements

To ensure optimal performance and longevity of water treatment equipment, regular maintenance is essential. Proper maintenance involves a range of tasks to keep your systems running smoothly.

Personnel training is crucial, ensuring that all staff are knowledgeable about operating procedures and maintenance protocols. Bacterial control is another key aspect, where factors like temperature, flow rates, and the use of biocides such as chlorine or UV disinfectants must be carefully managed to prevent contamination. Monitoring and data recording are vital for identifying trends and planning preventive measures.

Facility monitoring helps catch issues early on, preventing costly damages and downtime.

Equipment design, selection, and maintenance are fundamental in preventing inefficiencies and failures. Neglecting maintenance can lead to increased costs, system damage, and financial losses. By staying proactive with routine maintenance, you can save time and money in the long run, ensuring that your water treatment systems operate effectively and efficiently.

Future Innovations in Water Treatment

Innovations in water treatment technology are revolutionizing the industry with advancements in smart-water technologies and distributed water and wastewater plants. Here are four key future innovations shaping the water treatment landscape:

- Smart-Water Technologies: Utilizing cutting-edge sensor technology to enhance monitoring and control processes, improving operational efficiency and resource management.

- Leak Detection and Repair Strategies: Focus on developing proactive measures to identify and address leaks promptly, reducing water loss and enhancing system performance.

- Seawater Desalinization: Advancements in desalinization technologies offer promising solutions for freshwater scarcity, providing sustainable options for clean water production.

- Pollution Control: Innovations in pollution control methods aim to mitigate environmental impact, safeguarding water sources and promoting ecological sustainability.

These developments not only address current challenges in water treatment but also pave the way for a more sustainable and efficient future in water management.

Frequently Asked Questions

What Is the Main Problem in the Water Treatment Plant?

In the water treatment plant, the main problem revolves around outdated equipment, inadequate training, and regulatory hurdles. Addressing these issues is crucial for efficient operations, optimal water quality, and compliance with environmental standards.

What Are the Challenges of Water Purification?

Navigating modern water treatment challenges is like a complex puzzle. You must balance bacterial control, proper maintenance, instrumentation limitations, and regulatory hurdles. Success lies in ongoing training, vigilant monitoring, and strategic decision-making.

What Are Some Challenges Currently Facing Wastewater Treatment Facilities?

In modern wastewater treatment facilities, challenges like personnel training, bacterial control, monitoring, and maintenance, regulatory compliance, and operational expertise are crucial. Your plant's efficiency and success rely on addressing these obstacles effectively.

What Are the Problems With Water Filtration Systems?

When it comes to water filtration systems, you'll encounter challenges like bacterial growth control, equipment maintenance, and regulatory compliance. These obstacles require careful handling to ensure clean and safe water for all.

Conclusion

Now that you've navigated through the murky waters of modern water treatment obstacles, it's time to dive into the clear blue sea of future innovations.

Just like a skilled sailor steering through rough seas, with the right tools and knowledge, you can conquer any challenge that comes your way.

So, set sail towards a brighter, cleaner future in water treatment, where each wave brings new opportunities for growth and sustainability.

Ride the tide of innovation and make a splash in the industry!