Imagine water as the lifeblood of a pharmaceutical manufacturing facility, flowing through every process and ensuring the health of the final product. Just like the human body relies on a complex system to purify and circulate blood, pharmaceutical companies depend on sophisticated water treatment processes to maintain the purity and safety of their products.

From removing microscopic contaminants to eradicating harmful pathogens, the journey of water in pharmaceuticals is a tale of precision and excellence. As we explore the intricate world of water treatment in pharmaceuticals, you will uncover the essential steps taken to safeguard the quality and integrity of medications, laying the foundation for trust and reliability in the pharmaceutical industry.

Key Takeaways

- Water treatment technologies are essential in pharmaceutical operations, ensuring highly purified water for drug manufacturing and quality control.

- Regulatory compliance and continuous technological advancements play a crucial role in maintaining water purity and meeting industry standards.

- Utilizing methods like distillation, reverse osmosis, and UV treatment is vital in removing impurities and contaminants during pharmaceutical production.

- The importance of water quality in pharmaceuticals cannot be overstated, as it directly impacts product safety, efficacy, and patient health outcomes.

Importance of Water Purification in Pharmaceuticals

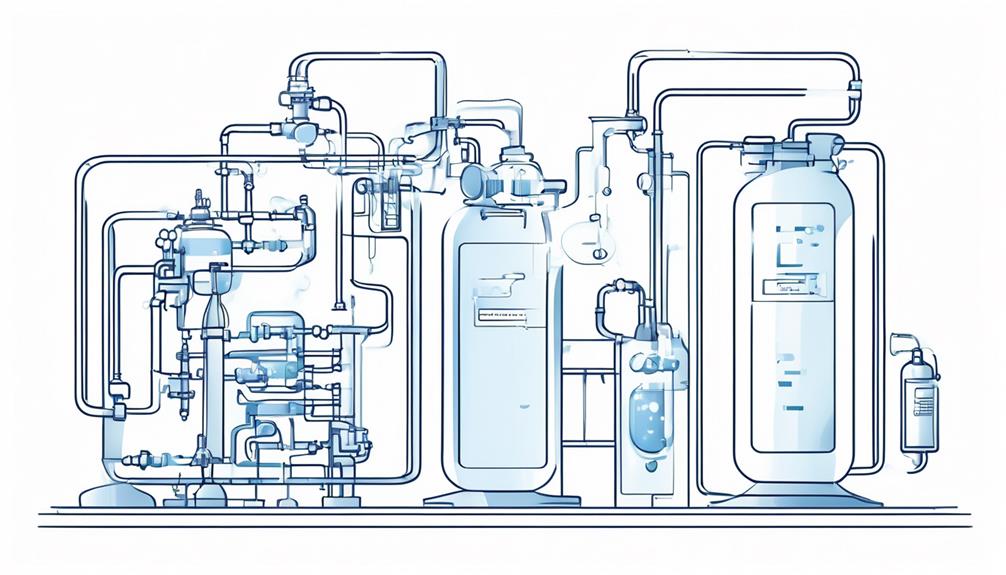

Water purification stands as the cornerstone of pharmaceutical operations, ensuring the purity and integrity of crucial pharmaceutical products. In the pharmaceutical industry, water plays a vital role in various processes, from drug manufacturing to quality control. Water Treatment Solutions are essential to provide highly purified water required for pharmaceutical operations. Water purification systems are meticulously designed to meet the stringent standards of the pharmaceutical industry, ensuring that water for injection (WFI) is free from impurities.

Manufacturing pharmaceutical products necessitates the use of treated water to prevent contamination that could compromise the safety and efficacy of medications. The advanced technologies employed in water purification guarantee that pharmaceutical companies adhere to regulatory guidelines, maintaining the highest standards of product quality. By continuously improving water treatment processes, the pharmaceutical industry can enhance the overall safety and effectiveness of medications, meeting the expectations of both regulators and consumers.

Key Water Treatment Technologies in Pharma

When it comes to water treatment technologies in the pharmaceutical industry, you'll find a range of methods designed to purify water effectively.

Methods such as distillation, reverse osmosis, and electric de-ionization play a crucial role in ensuring high-quality water for pharmaceutical production.

These technologies are essential for removing impurities and contaminants to meet the strict standards required for pharmaceutical manufacturing.

Purification Methods Overview

Delve into the world of pharmaceutical water treatment technologies with a comprehensive overview of key purification methods used in the industry.

When it comes to purifying water for pharmaceutical manufacturing, several crucial techniques are employed:

- Reverse Osmosis: Removes impurities by pushing water through a semipermeable membrane.

- Ultrafiltration: Filters water by using a membrane with fine pores, removing contaminants.

- Distillation: Boils water and collects the purified condensation, leaving impurities behind.

- Ion Exchange: Swaps ions in the water with ions attached to a resin, purifying the water.

- UV Treatment: Exposes water to UV light to kill bacteria, viruses, and other microorganisms.

These processes play a vital role in ensuring the quality and safety of pharmaceutical water used in production.

Application in Production

Moving from an overview of purification methods, you now witness the practical application of key water treatment technologies in pharmaceutical production.

In the pharmaceutical and medical industries, water purification plays a vital role in ensuring the safety and efficacy of pharmaceutical products. During production processes, treatment systems such as distillation, reverse osmosis, electric de-ionization, UV filtration, and physical separation techniques are utilized to remove pollutants and contaminants.

These water treatment processes guarantee the production of sterile and pure water that meets stringent quality standards required for pharmaceutical use. By employing various purification techniques like chlorination, dosing, and filtration, pharmaceutical industries maintain compliance with regulatory guidelines and uphold the highest quality requirements essential for drug manufacturing.

Regulatory Requirements for Water Treatment

To ensure the safety and efficacy of pharmaceutical products, meeting stringent regulatory requirements for water treatment is essential. Compliance with regulatory standards is crucial in pharmaceutical manufacturing processes to prevent contamination and maintain the quality of treated water.

Key aspects of regulatory requirements for water treatment in the pharmaceutical industry include:

- Adherence to Quality Standards: Water treatment systems must meet industry guidelines to ensure the purity of water used in pharmaceutical manufacturing processes.

- Continuous Technological Advancements: Regulatory standards emphasize the importance of advancements in water purification technologies to enhance the quality and safety of pharmaceutical products.

- Importance of Compliance: Pharmaceutical facilities must adhere to regulatory requirements to guarantee the quality and safety of water used in drug manufacturing.

- Enhanced Safety Measures: Utilization of UV sanitation and water softening treatments in water treatment facilities to ensure the distribution of clean and safe water.

- Quality Assurance: Meeting regulatory requirements is fundamental for water treatment providers to maintain the integrity of water treatment and distribution processes.

Challenges in Pharmaceutical Water Treatment

Navigating the complex landscape of pharmaceutical water treatment poses significant challenges in maintaining water purity and safety to meet stringent quality requirements for drug manufacturing. In pharmaceutical manufacturing, ensuring the consistent delivery of treated water that meets various purity levels is crucial.

Water treatment systems must effectively address different contaminants using purification techniques like distillation, reverse osmosis, UV filtration, and de-ionization. The industry demands three tiers of treated water – purified, highly purified, and water for injection – to support diverse pharmaceutical processes.

Meeting these demands while adhering to regulatory standards requires managing water treatment processes meticulously to prevent contamination. Continuous advancements in water purification technology aim to enhance the quality and safety of pharmaceutical products. By overcoming the complexities of water treatment challenges, pharmaceutical companies can uphold the integrity of their manufacturing processes and ensure the production of high-quality medicines.

Best Practices for Water Purification

Amid the intricate landscape of pharmaceutical water treatment challenges, implementing best practices for water purification is essential for maintaining the integrity and quality standards of drug manufacturing processes. To ensure high-quality water for pharmaceuticals, follow these best practices:

- Proper Water Treatment: Begin by treating feed water to eliminate pollutants and contaminants effectively.

- Efficient Systems: Utilize distillation and reverse osmosis for their efficiency in purifying water to meet safety standards.

- Electric De-Ionization: Use this method to produce de-ionized water by removing salts, minerals, and organic contaminants.

- Additional Purification Methods: Consider other systems like UV filtration and boiling water to further purify water for pharmaceutical manufacturing.

- Stringent Quality Requirements: Water purification is crucial to meet the stringent quality requirements necessary for drug manufacturing processes.

Future Trends in Pharma Water Treatment

In the realm of pharmaceutical water treatment, the future is shaping up to prioritize sustainability, regulatory compliance, and innovative technology integration. Advancements in pharmaceutical water treatment are steering towards ensuring high water quality standards through techniques like UV filtration and electric de-ionization.

The pharmaceutical industry is increasingly recognizing the importance of tailored water treatment solutions for healthcare and pharmaceutical facilities. Ongoing developments in water purification technology aim to enhance the safety, efficacy, and quality of pharmaceutical products.

Providers are now focusing on creating comprehensive water management programs to meet specific purity and safety requirements within the pharma industry. With a keen eye on sustainability and regulatory standards, the future of pharmaceutical water treatment lies in embracing cutting-edge methods to purify water, ensuring it meets the stringent quality control measures essential for pharmaceutical manufacturing.

Water recycling and advanced treatment processes are set to revolutionize how treated water is utilized in pharmaceutical water systems, paving the way for a more environmentally friendly and efficient approach in the industry.

Frequently Asked Questions

What Are the Processes of Water Treatment in Pharmaceutical Industry?

To treat water in pharmaceuticals, you purify feed water by removing pollutants. Methods like distillation and reverse osmosis effectively clean water. Electric De-Ionization eliminates salts and minerals. UV filtration and boiling water are also used.

What Are the 5 Processes of Water Treatment?

You start with pre-treatment like chlorination, move on to distillation and reverse osmosis for removing contaminants, and consider additional methods like electric deionization and UV filtration. Various purification systems are vital for water quality.

What Are the 7 Methods of Water Treatment?

You've asked about 7 methods of water treatment. From pre-treatment to distillation and reverse osmosis, purification techniques like electric de-ionization and UV filtration are crucial. They ensure safety and quality in pharmaceutical manufacturing.

What Are the Methods of Pharmaceutical Wastewater Treatment?

When treating pharmaceutical wastewater, you'll go through preliminary steps, aeration, and filtration to remove contaminants. Distillation, reverse osmosis, and de-ionization are used for water purification. UV filtration, boiling, and physical separation methods ensure strict quality standards.

Conclusion

So, remember, keeping your pharmaceutical water clean is like giving your products a refreshing spa day.

By using top-notch purification techniques and staying on top of regulatory guidelines, you're ensuring that your medications are safe, effective, and ready to work their magic.

Stay ahead of the game, and your water treatment processes will flow smoothly like a crystal-clear stream, keeping your pharmaceuticals in tip-top shape.

Keep up the good work!